The 7-Second Trick For Digital Printing

The 7-Second Trick For Digital Printing

Blog Article

Get This Report about Digital Printing

Table of ContentsAll about Digital PrintingDigital Printing Things To Know Before You BuyFacts About Digital Printing Uncovered

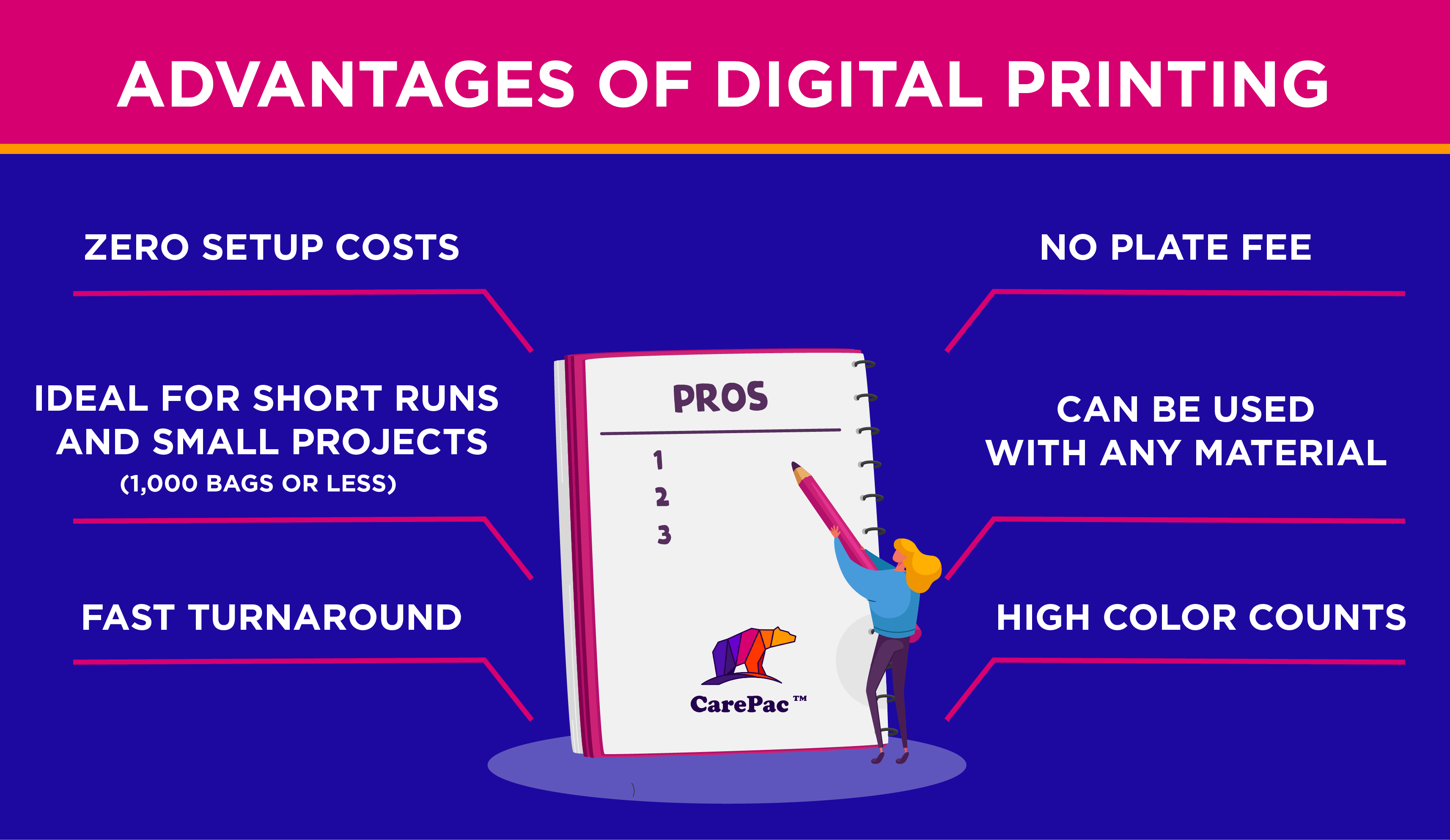

The liquid ink abides by the substrate through an electrostatic cost, making certain lively colours and sharp information. Digital printing likewise requires minimal setup. Although modern lithographic technology has lowered arrangement times to around 15 minutes, digital printing still brings about benefit with its near-instant preparedness. In addition, electronic prints completely dry instantaneously, unlike lithographic prints, which call for 2-3 hours to completely dry. This removes smearing threats and the requirement for drying out shelfs. Below are the crucial methods which electronic printing sustains greener practices: One of the significant ecological advantages of digital printing is decreasing waste. Traditional printing approaches, like lithographic printing, often waste considerable amounts of paper and ink during the arrangement phase. Digital printing gets rid of the requirement for plates and other consumables, reducing waste throughout the production process. A few of the most typical applications include: Digital printing is excellent for creating calling card, flyers, posters and various other marketing materials. It permits quick turn-around times and cost-effective production, specifically for businesses with smaller sized print runs. Digital printing is progressively utilized in the packaging industry to produce special, custom-made packaging.

Digital printing machine remove the need for these plates, significantly minimizing configuration expenses. Digital printing machine can include variable data right into your prints, which allows for extremely tailored marketing products (Digital Printing). By individualizing your advertising materials, you can enhance involvement with possible clients and boost the possibilities of transforming them right into real consumers

Digital printing machine offer excellent color uniformity and accuracy, causing better prints. With electronic printing, you can be certain that the color of your prints will certainly correspond from one print task to the following. A number of years ago, numerous consumers did not accept direct-injection digital click resources printing due to the fact that the high price. The purchase expense of a set digital printing devices goes to the very least 150%of the traditional printing and coloring imp source tools, which enhances the.

Unknown Facts About Digital Printing

In order to prevent corrosion of the nozzle, the ink for electronic printing is extra expensive than the ink for standard printing, and additional ink filtration is needed during the printing procedure. In electronic inkjet printing, the pattern is directly published on the material, getting rid of the plate making in rotary display printing. Yes, are a lot more pricey than conventional printing inks, yet the digital printing process can save ink consumption.

Today, the digital direct-injection printing press has actually gone from proofing to the phase of medium-sized and large-sized production. The electronic direct-injection device has experienced the promotion duration and went into the growth and maturity duration. Both printing homes and brand name owners know the advancement capacity of digital printing, and want to enhance financial investment in digital printing. The print quality can often even competing that of countered printing. Digital printing is extra cost-effective for brief print runs due to the fact that it requires less pre-press activities and less arrangement than countered printing. If a mistake in balanced out printing is not captured prior to the plates are made, it will certainly be extremely expensive to make new ones. While everybody truly wishes that errors will be stayed clear of, it is reasonable to prepare for their prospective correction. In enhancement, its precision is very high. This makes certain harmony in appearance throughout the board, reducing the possibility that any type of item will certainly need to be tossed out as a result of defects. Making certain the navigate here plates remain in location, the ink trick is adjusted, and all the needed modifications have actually been made is a taxing process when offset printing. Reduced pre-press steps imply much less time is needed to establish the press initially. This causes a marked acceleration of turn-around time. When you need published products quickly, this is an excellent alternative. Digital printing can be a lifesaver when you obtain an order in the nick of time.

Variable information printing, such as direct mail with personalized codes and addresses, is preferably fit for digital printing. Digital quick printing only requires four steps of style, testimonial, printing and binding to get whatever done. Digital fast printing has an unequaled benefit: print on need.

Report this page